Mechanical Engineering BMM. Exam 7 May.

Sometimes Paper Is Your Best Prototyping Tool Even If You Re Nintendo Prototyping Tools Interactive Design Rapid Prototyping

Abstract injection moulded components are consistently designed to minimize the design and manufacturing information content of the enterprise system.

. Design of Experiments DOE A designed experiment is nothing but a systematic study of the effects of variables on the quality of the part. Sign-up For Free Today. Provides an overview of how to design an experiment.

4 A Walk-Through Taguchi Design of Experiment DOE Application 812008 Example. Several experimental design strategies may be considered for improving injection molded product quality based on process parameter evaluation. For example at 800 psi of hold pressure the part length is 1726 inches and at 1200 psi the length is 1740.

Radial flow severe distortion. The Optimization of Injection Molding Processes Using Design of Experiments PrOblEM Manufacturers have three primary goals. Sign-up For Free Today.

Analyzes how data is used to characterize optimize and troubleshoot an injection molding process. An Experimental Study to Reduce Short-Shots in Cooling Fan Molding Process Quality Characteristic. The Taguchi Design Method Various Modeling Designs.

Free Online Training Demos. Kim and James W. Design of Experiments for.

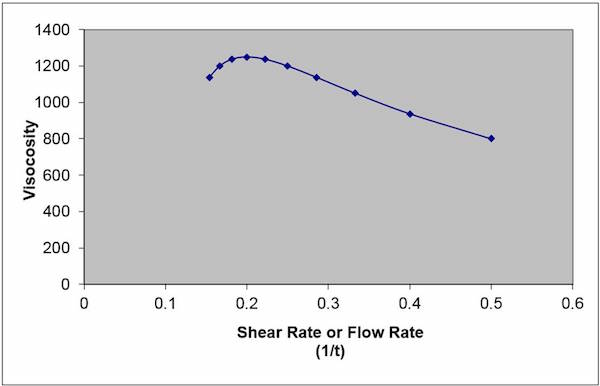

A study of the effect of holding pressure on the length of the part is a designed experiment. Explores various DOE techniques. 81 Parameters in Injection Molding 145 8 Design of Experiments for Injection Molding Planned experiments have been around for centuries.

Reduce rejects due to Short-Shots. Analyzes how data is used to characterize optimize and troubleshoot an injection molding process. Explains how to collect and analyze the data using real-world molding examples.

In the 17th century a doctor planned some experiments to find a cure for an ailment of that day. Experience and reference works may tell us that several factors may be responsible such as mould temperature injection speed type of plastic resin used and so on. Design for Injection Molding pp 319 - 359.

The example timeline in the gantt chart is based on the sample part shown below using a single cavity mold. Injection molding lab report. Samplepractice exam 29 October 2017 questions and answers.

Injection molding is a manufacturing process commonly used for fabricating items from plastic trinkets and toys to automotive body parts cell phone cases water bottles and containers. He engaged various patients and various combinations of medicines to find the right cure. 1 produce goods that meet customer specifications.

As an example consider a plastic injection moulding process which may create parts that shrink too much. We cannot directly observe what is occurring to cause the shrinkage. Gate Location and Warping Center gate.

This ppt contains the working of injection molding machine type of plastic granules used reshaping the old plastic products into a new shape and design the clamping mechanism used and lots more. Ad Facilitates Mass Production - Make Lots of Parts Fast Inexpensively Exactly to Spec. Analysis of the results shows a combination of temperature and setting time as the most significant factor.

From past experience the team strongly felt that weight of production part bears a. The overall part size is 95520 x 55541 x 16500 mm made of a general-purpose PCABS. Ad Free On-line Training Lessons.

Desirable performance - Bigger is Better. Wubken Influence of processing conditions on Molecular Orientation in Injection Molds V35cms V8cms sample Transverse direction 22. 4 A Walk-Through Taguchi Design of Experiment DOE Application 812008 Example.

Weight of the part in ounce. Explains how to collect and analyze the data using real-world molding examples. A strategy for planning research known as design of experiments DOE was first introduced in the early 1920s when a scientist at a small agricultural research station in England Sir Ronald Fisher showed how one could conduct valid experiments in the presence of many naturally fluctuating conditions such as.

Free Online Training Demos. Ad Free On-line Training Lessons. It is a quick process to create a mass amount of identical plastic parts.

A plastic molding workshop wants to reduce injection molding rejects and thus perform a set of experiments which change injection pressure mix temperature and setting time. Provides an overview of how to design an experiment. Describes other experimental design-types that should be considered when conducting Design of Experiments for an injection molding process.

2 improve process efficiency in cycle times labor cost and energy consumption. Taguchi Box Behnken Central Composite Circumscribed Central Composite Faced and D-Optimal designs. Download the free Injection Molding Gantt Chart.

3 increase process robustness by reducing sensitivity to small. Essentially many of the plastic parts that we use in every-day life are injection molded. Explores various DOE techniques.

Working With Polymers Poster Blown In Insulation Extrusion Polymer Molding

Artstation Sci Fi Port Modular Environment Roma Voronin Romix Sci Fi Sci Environment

What Is Design Of Experiments Doe In Scientific Molding

3d Printed Linear Motion Mvmt 92 17 Steps With Pictures Mechanical Design Mechanical Engineering Design Linear

Design Of Experiments Doe For Injection Molding Youtube

Pdf Plastic Injection Process Volume 3 Injection Machines Mold Design And Standards Design Of Experiment Moldflow Catia

0 comments

Post a Comment